Welcome to Onyx

Lint Cleaning

The ginned fiber (now referred to as lint) must be processed through some level of lint cleaning. Depending upon whether the gin plant is processing Upland or ELS cotton, the lint cleaning arrangement for the facility will vary. Lummus manufactures both centrifugal (air-type) and mechanical (saw-type) lint cleaners for Upland cotton, along with specialized mechanical and textile-type lint cleaning for ELS cotton (roller gin plants). Configuration of these systems will vary, based on the level of trash in the lint. Lummus lint cleaning has long been shown to be the best at effective cleaning while minimizing fiber damage.

The Process

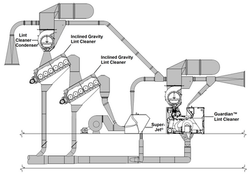

Now that the lint has been separated from the seed, it goes through some level of lint cleaning. Once again, depending upon whether the gin plant is processing Upland or ELS cotton, the lint cleaning specifications for the facility will be different. For saw-type gin plants, the first lint cleaner is typically a Lummus Super-Jet® Lint Cleaner, installed directly behind the saw-type gin stand. The Super-Jet®, which was pioneered by Lummus, uses centrifugal force to remove contamination from the lint. It is the only type of lint cleaner that does no fiber damage, since it has no moving parts.

From the Super-Jet®, the lint will be sent to either single (1) or tandem (2) saw-type lint cleaners, depending upon the amount of contamination in the lint. The saw-type lint cleaner combs the fibers while whipping them across grid bars that force the trash out into an air stream that pull them away from the saw. Lummus offers two types of saw-type lint cleaners in its product line. The most popular is the Lummus-exclusive Sentinel™ II Lint Cleaner (available in 108” and 144” widths), which does not condense the lint into a batt, but rather, feeds the individual tufts of lint onto the saw cylinder, reducing the aggressive action of the saw, and resulting in improved fiber properties within the sample (less short fiber content, less neps, better uniformity). For regions that continue to prefer the appearance of lint produced by a conventional controlled-batt, saw-type lint cleaner, the market-proven Lummus Model 108 Lint Cleaner continues to meet that need.

For ELS cotton, lint cleaning will consist of either a series of cylinder-type inclined cleaners feeding a Super-Jet® Lint Cleaner or the Lummus-exclusive Guardian™ Lint Cleaner. The Guardian™ features a lint condenser that feeds the lint batt onto a textile-type beater cylinder, which, in turn, feeds an integral Super-Jet® Lint Cleaner. In order to maintain their desired fiber properties, no saw-type lint cleaning is ever used on ELS cottons.

|  |

|---|

Available Options

-

Super-Jet® Lint Cleaner (Upland or ELS cotton) (94”, 120”, and 144” widths available)

-

Sentinel™ II Lint Cleaner (Upland cotton) (108” and 144” widths available)

-

Model 108 Lint Cleaner (Upland cotton)

-

Guardian™ Lint Cleaner (ELS cotton